- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-10-14 Origin: Site

The welding method you choose for aluminum directly determines joint strength, dimensional accuracy, and service life. Among the three most widely used processes—Friction Stir Welding (FSW), MIG (Metal Inert Gas), and TIG (Tungsten Inert Gas)—each has distinct advantages.

FSW is a solid-state process delivering high mechanical strength and minimal distortion.

MIG provides high productivity and easy automation.

TIG offers unmatched precision and visual quality on thin aluminum.

When the goals are structural integrity, fatigue resistance, and low distortion, FSW is often the superior choice for aluminum assemblies.

Friction stir welding, is a solid-state joining process, meaning no melting occurs. A rotating tool—comprising a shoulder and pin—is plunged into the joint line between two aluminum plates. Frictional heat softens (plasticizes) the material, and the stirring action forges it together under pressure. As the tool traverses the seam, the plasticized metal consolidates behind it, forming a fine-grained, defect-free nugget zone.

Because the metal remains below its melting point, FSW avoids fusion-related defects such as porosity, solidification cracking, and segregation. The process produces a narrow heat-affected zone (HAZ) and retains excellent mechanical properties.

Engineering Note: FSW creates a dynamically recrystallized microstructure with small equiaxed grains, offering superior strength and fatigue performance.

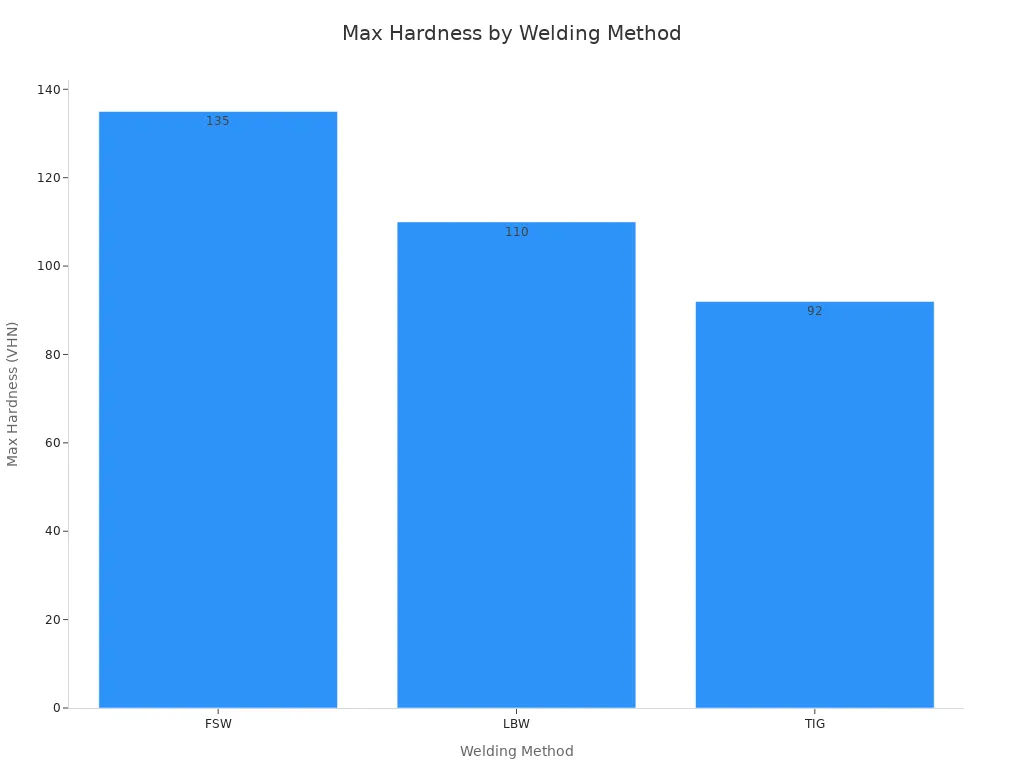

Welding Method | Heat-Affected Zone | Maximum Hardness (VHN) |

|---|---|---|

FSW | Narrow | 135 |

TIG | Wider | 92 |

TIG (GTAW) is a fusion process that uses a non-consumable tungsten electrode and inert shielding gas (commonly argon). The electric arc generates temperatures above 6,000 °C, melting the base metal and filler rod. As the molten pool solidifies, it recrystallizes into a cast microstructure.

This “melting and recrystallization” mechanism produces smooth, aesthetic welds with precise control over penetration and bead geometry. However, fusion welding of aluminum leads to a wider HAZ and potential overaging or coarsening in heat-treatable alloys (such as 6xxx), reducing post-weld strength.

Engineering Note: TIG welding excels in thin or decorative aluminum applications—such as aerospace skins, custom panels, or bicycle frames—where appearance and control outweigh speed.

MIG (GMAW) welding feeds a continuous consumable wire electrode through a torch while shielding gas protects the weld pool. It is fast, semi-automated, and easily adapted for large-scale fabrication.

However, aluminum’s high thermal conductivity and oxide layer (melting at ~2,050 °C) introduce challenges: poor penetration, porosity, and hot cracking if cleaning and heat input are not controlled. MIG is excellent for productivity but requires strict process discipline for aluminum quality.

| Aspect | FSW (Friction Stir Welding) | MIG (Metal Inert Gas) | TIG (Tungsten Inert Gas) |

|---|---|---|---|

| Process Type | Solid-state (no melting) | Fusion (melting) | Fusion (melting & recrystallization) |

| Typical HAZ Width | Very narrow | Moderate | Wide |

| Tensile Strength (6061-T6) | 70–90% of base (≈ 340 MPa) | 180–240 MPa | 200–230 MPa |

| Microstructure | Fine, dynamically recrystallized | Cast + HAZ softening | Cast + overaged HAZ |

| Surface Finish | Clean, minimal defects | Moderate spatter | Excellent, smooth |

| Speed / Productivity | Very fast (ideal for automation) | Fast | Slow |

| Consumables | None (no filler/gas) | Wire + gas | Tungsten + gas + filler rod |

| Environmental Impact | Very low | Moderate | Moderate |

| Skill Requirement | Medium (setup skill) | Low | High |

| Typical Use | EV battery trays, aerospace panels, marine parts | Frames, chassis, structures | Thin panels, artistic welds |

FSW is a great way to join aluminum. It makes strong and clean welds. You do not melt the metal. A spinning tool mixes the aluminum together. This helps stop problems like cracks or tiny holes. You can join many types of aluminum, even die-cast ones. You do not need to worry about weak spots or hot cracks.

Zhihui Welding’s Friction Stir Welding Machine makes FSW even better. You can weld all aluminum alloys, from 1xxx to 7xxx series. The machine works for thick and thin parts, up to 20 mm. The welds do not leak, which is good for cars and boats. Welds stay strong and do not get tired or break easily. You can bend or shape the welded parts after joining. They will not crack.

Tip: FSW is good for battery trays, cooling plates, and big aluminum panels. You can use it for busbars, electronics, and shipbuilding.

Here are some reasons why FSW is a top choice for aluminum:

Joins many aluminum grades without cracks or tiny holes.

Gives great heat and electricity flow.

Works with all aluminum alloys and die-cast aluminum.

Lets you bend welded parts without cracking.

Makes strong welds that last a long time.

Good for thick and thin aluminum pieces.

MIG welding is fast and easy to learn. You use a wire and shielding gas to join the metal. Many jobs use MIG for cars, buildings, and factories. You can weld thick or thin aluminum parts.

But MIG has some problems with aluminum. Aluminum moves heat away quickly. This makes it hard to keep the weld hot. You must clean the surface well. If you do not, the weld can be weak. Tiny holes and cracks can happen if you do not control the process.

Challenge | Description |

|---|---|

Porosity | Tiny holes can form in the weld and make it weak. |

Cracking | Too much heat can cause cracks in the aluminum. |

Oxidation | A thin layer forms on aluminum and melts at a higher temperature. |

Thermal Conductivity | Aluminum moves heat away fast, so welding is harder. |

You can use MIG for many aluminum jobs. But you need to watch out for these problems. If you want speed and flexibility, MIG is a good pick. You see it in car frames, trailers, and buildings.

TIG welding gives you lots of control with aluminum. You use a tungsten electrode and can add filler metal. TIG makes neat and clean welds. You can weld thin aluminum parts very carefully.

Many people use TIG for planes, cars, and factories. You can weld many metals, not just aluminum. TIG is best for detailed or fancy welds.

TIG welding has some problems with aluminum. You must keep the surface very clean. The oxide layer can cause trouble. TIG is slower than MIG or FSW. You may see tiny holes or cracks if you do not control the heat.

Note: TIG is great for small and careful aluminum parts, like bike frames or custom car panels.

Advantages | Industry Applications | |

|---|---|---|

FSW | Joins different materials, makes high-quality welds | Aerospace, Automotive |

MIG | Fast, flexible, makes good welds | Automotive, Construction, Manufacturing |

TIG | Precise, can weld many metals and alloys | Aerospace, Automotive, Manufacturing |

When you look at the costs of different welding methods for aluminum, you need to think about more than just the price of the machine. You also have to consider maintenance, materials, and how much time you spend on each job. This comparison will help you see the differences between FSW, MIG, and TIG.

| Parameter | FSW | MIG | TIG |

|---|---|---|---|

| CapEx | High (machine, fixture) | Low | Medium |

| OpEx | Low (no filler/gas) | High (wire/gas/maintenance) | Medium–High (electrodes, power) |

| Cycle Time | Short (automated) | Short–Medium | Long |

| Rework Rate | Minimal | Moderate | Low |

| Long-term ROI | Excellent for high volume | Good for general fab | Fair (precision niche) |

Friction Stir Welding (FSW) machines often cost more at the start. You pay for advanced technology and strong equipment. However, you save money over time. The tools last a long time and can weld many parts before you need to replace them. You do not need filler wire or shielding gas, so you avoid those extra costs. FSW also uses less energy because it does not melt the metal. If you work on big projects or need to weld many aluminum parts, FSW can be a smart investment.

Tip: FSW helps you lower your long-term costs by reducing waste and cutting down on repairs.

Welding Technique | Maintenance Costs Description |

|---|---|

Tools are durable and can weld significant lengths, reducing the need for frequent replacements. | |

MIG Welding | Requires filler materials and shielding gas, which contribute to recurring expenses. |

TIG Welding | Involves costs for tungsten electrodes that wear out and need replacement, along with high energy consumption. |

MIG is popular because the machines cost less than FSW. You can start welding quickly. However, you need to buy filler wire and shielding gas for every job. These supplies add up over time. You also need to clean your equipment often. If you weld a lot, the recurring costs can become high. In this comparison, MIG gives you a lower entry price but higher ongoing expenses.

TIG welding equipment sits in the middle for price. You pay for a quality machine and special tungsten electrodes. These electrodes wear out and need replacing. TIG uses more electricity, which can raise your energy bills. You also need to buy filler rods for some jobs. In this comparison, TIG costs more to run than MIG, especially if you weld often or work on large projects.

Note: Always think about both the starting price and the long-term costs when you make your comparison.

Example: For a 1 m FSW joint on 6 mm aluminum, cycle time is typically 30–40 s with <1% rework, versus 90–120 s for MIG and ~180 s for TIG.

When you choose friction stir welding for aluminum, you get strong and reliable joints. The process does not melt the metal. Instead, it stirs the edges together. This makes the weld almost as strong as the original aluminum. You can see the difference in tensile strength in the table below:

Welding Method | Tensile Strength (MPa) |

|---|---|

FSW | 340 |

MIG | 232 |

Base Metal | 400 |

FSW joints also stand out for their excellent fatigue resistance. You can trust these welds to last a long time, even when the parts move or vibrate. Here are some key points about FSW fatigue performance:

FSW joints show better fatigue resistance than traditional fusion welds.

Special tests prove that FSW joints hold up well in real-world structures.

FSW welds often perform better than MIG and TIG welds when it comes to repeated stress.

Tip: If you need strong, long-lasting aluminum parts, FSW is a top choice.

MIG welds give you good strength, but not as much as FSW. The process melts the metal and uses a filler wire. This can create small weak spots. The tensile strength for MIG welds on aluminum is about 232 MPa. You may notice that MIG welds do not handle repeated bending or vibration as well as FSW. Over time, MIG welds can develop cracks if the part moves a lot.

MIG welds work well for many jobs, but they may not last as long under heavy use.

You should check MIG welds often if your parts face lots of stress.

TIG welding lets you make neat and precise welds on aluminum. You use a tungsten electrode to control the process. TIG welds look clean and smooth. The strength is good for thin parts or detailed work. However, TIG welds do not match the fatigue resistance of FSW. If your parts need to handle lots of movement, TIG may not be the best option.

TIG welds are great for small, careful jobs.

You get a nice finish, but not the highest strength for heavy-duty use.

You will notice that friction stir welding stands out for its efficiency. The welding process uses a rotating tool that moves along the joint. This tool creates heat through friction and stirs the metal together. You do not need to stop for filler wire or gas. The process works quickly, especially for long, straight seams. You can weld thick or thin aluminum parts in one pass. Many factories use FSW for battery trays and large panels because it saves time. You also get less distortion, so you spend less time fixing parts after welding.

Tip: FSW works well for automated production lines. You can set up the machine and let it run with little supervision.

MIG welding gives you fast results. You feed a wire into the weld pool, and the process keeps going as long as you have wire and gas. You can weld thick and thin aluminum parts. Many people use MIG when they need to finish jobs quickly. The welding process is easy to learn, so you can train workers fast. You may need to stop to change wire spools or gas tanks, but you can still finish large projects in a short time. MIG works well for car frames, trailers, and building structures.

MIG is a good choice when you want speed and flexibility.

You can weld in many positions, even overhead.

TIG welding takes more time than FSW or MIG. You use a tungsten electrode and may add filler metal by hand. The welding process gives you control, but you must move slowly to keep the weld clean. TIG works best for small or detailed jobs. You may spend more time on each part, but you get a neat finish. Many people use TIG for custom work or repairs. If you need to weld thin aluminum or make artistic seams, TIG is a good option.

Welding Method | Speed | Best Use Case |

|---|---|---|

FSW | Very Fast | Long seams, automation |

MIG | Fast | Large projects, flexibility |

TIG | Slow | Precision, small parts |

Friction stir welding is used in many industries. These industries need strong and light aluminum parts. In cars, FSW joins battery trays and cooling plates. It also connects chassis parts. This makes cars lighter and saves energy. Electronics use FSW for busbars and enclosures. These welds are clean and reliable. FSW is also found in aerospace, marine, and defense. These fields need strong aluminum welds for safety. They also need good weldability for performance.

Zhihui Welding’s Friction Stir Welding Machine works for all sizes. You can weld thin panels or thick pieces. The machine fits small and big jobs. It works for single parts or large batches. Here is a table that shows where FSW is used and why it helps:

| Industry | Preferred Method | Reason |

|---|---|---|

| Aerospace | FSW / TIG | Strength and precision |

| Automotive | FSW / MIG | High speed, lightweight structures |

| Marine | FSW | Corrosion-resistant, leak-tight welds |

| Construction | MIG | Versatile and fast |

| Defense | FSW | Structural integrity and fatigue performance |

MIG welding is popular for home and workshop projects. You can use MIG to join aluminum frames and bike parts. It also works for fixing tools. MIG is easy to learn and fits many part sizes. You get fast results with thin or thick aluminum.

FSW needs special equipment for home use. Most DIY users pick MIG or TIG for their aluminum projects. MIG is quick. TIG gives more control for small and detailed work. Always check if your aluminum parts can be welded before you start.

Tip: Pick the welding method that fits your project size. Think about the type of aluminum and the finish you want. For big jobs, FSW gives strength and good welds. For small or creative projects, TIG and MIG offer flexibility.

When you choose a welding method for aluminum, you need to look at several important factors. Each project has its own needs. You want to match the method to your goals. Here is a table to help you compare the main points:

Factor | Description |

|---|---|

Material Type | Some methods work better for certain aluminum alloys. TIG is good for thin aluminum. |

Material Thickness | Thin parts need careful heat control. TIG works well here. Thick parts may use MIG for deep welds. |

Welding Position | MIG lets you weld in many positions. This gives you more flexibility. |

Quality and Aesthetics | TIG makes clean and neat welds. You get less spatter and a nice finish. |

Speed and Efficiency | MIG works faster than TIG. This helps when you have a tight schedule. |

Welder Skill and Experience | TIG needs more skill. Automation can help if you are new to welding. |

Cost Considerations & ROI | Each method has different costs. Automated MIG or TIG can save money over time. |

The best method for your aluminum project depends on many things. You should think about the thickness of the material, the purpose of the part, and the type of aluminum alloy.

You also need to think about your budget and the quality you want. FSW gives you strong, clean, and consistent welds. It does not melt the metal, so you avoid problems like porosity and distortion. This makes FSW a good choice for high-quality jobs, even though it costs more at the start.

You can make strong and clean aluminum welds with fsw. This is very helpful if you use al-6061. Zhihui Welding’s machines help your welds last longer and look nice. When you choose a welding method, think about your project size. Also, check how thick your material is. Decide what kind of finish you want.

FSW makes joints that are stronger and look better.

MIG is good for quick jobs and thick parts.

TIG works best for thin pieces and careful work.

Benefit | Description |

|---|---|

FSW makes welds that are tough and do not leak. | |

Improved surface finish | Welds look smooth and neat. |

Lower environmental impact | FSW helps make things in a greener way. |

If you want to weld aluminum well, Zhihui Welding can help you with their skills and tools.

| Design Factor | Recommended Process | Notes |

|---|---|---|

| Material Thickness ≤ 2 mm | TIG | AC balance & pulse control prevent burn-through |

| 2–6 mm (medium gauge) | FSW / MIG | FSW for long straight seams; MIG for multi-position |

| ≥ 6 mm (heavy sections) | FSW | One-pass capability, low distortion |

| Length > 300 mm (linear seam) | FSW | Best ROI for automation |

| Complex or short welds | TIG / MIG | Higher flexibility |

| Gas-tight / fatigue-critical parts | FSW > TIG > MIG | FSW preferred for cooling plates, enclosures |

| Aluminum Series | Fusion Weldability | Typical Filler (MIG/TIG) | Notes |

|---|---|---|---|

| 1xxx / 3xxx | Excellent | 1100 / 4043 | High conductivity, clean oxide |

| 5xxx | Very good | 5356 / 5183 | Strong, ductile joints |

| 6xxx | Good | 4043 / 5356 | Risk of HAZ softening; FSW recommended for critical parts |

| 2xxx / 7xxx | Poor | Special filler or none | FSW preferred—fusion prone to hot cracking |

FSW: Governed by ISO 25239 for aluminum and its alloys.

Fusion (MIG/TIG): Acceptance per AWS D1.2 and ISO 10042 (Levels B–D).

Testing Methods:

Mechanical: ASTM E8 (tensile), ASTM E466 (fatigue)

NDT: Penetrant, radiography, phased-array ultrasonic

FSW Process Monitoring: Real-time torque, axial force, temperature control

Common Defects

Fusion welds: porosity, lack of fusion, hot cracking, undercut

FSW: tunnel voids, kissing bonds, surface groove (prevented by proper tool design and clamping)

FSW produces no fumes, no filler waste, and minimal post-processing, making it one of the most sustainable aluminum welding solutions. Energy consumption per joint is up to 30–40% lower than comparable fusion welds.

Sustainability Highlight: No shielding gas → zero greenhouse emissions from argon/helium; no spatter → less scrap

When evaluating total cost of ownership:

TCO=CapEx+OpEx+Quality Loss−Productivity Gains

Empirically, when joint length > 300 mm, annual volume > 5,000 parts, or leak/fatigue rejection rate < 1%, FSW demonstrates a lower TCO than MIG or TIG.

FSW – Solid-state, high strength, low distortion, long-term stability.

MIG – High speed and flexibility for general fabrication.

TIG – Precision, cleanliness, and superior finish for thin or decorative aluminum.

For most industrial aluminum applications—especially where mechanical strength, fatigue life, or leak integrity are critical—Friction Stir Welding (FSW) provides the most robust and sustainable solution.

In essence:

FSW stirs and bonds,

MIG melts and fills,

TIG melts and recrystallizes.

Each serves a purpose; choose based on design, alloy, and production scale.

You get stronger, cleaner welds with FSW. The process does not melt the metal, so you avoid cracks and weak spots. FSW works well for many aluminum types and gives you reliable results.

You can use MIG and TIG for most aluminum alloys. Some alloys may need special filler rods or settings. Always check the alloy type before you start welding.

Yes! FSW does not use filler wire or shielding gas. You avoid harmful fumes and reduce waste. This makes FSW a greener choice for welding aluminum.

You need some training to use an FSW machine. The process is easy to learn with the right guidance. Zhihui Welding offers support and training for new users.

Zhihui Welding provides full-process Friction Stir Welding systems for aluminum alloys from 1xxx to 7xxx series, including die-cast materials up to 20 mm thick.

Our equipment integrates:

Closed-loop control of torque, axial force, and temperature

Real-time monitoring per ISO 25239

Automatic tool wear compensation

Leak testing and surface finishing integration

Applications: EV battery trays, cooling plates, busbars, marine panels, aerospace structures.

Result: Strong, clean, fatigue-resistant welds with up to 40% lower total manufacturing cost。

FSW leads the next era of aluminum joining—stronger, cleaner, and more efficient.

For advanced solutions, trust Zhihui Welding to bring solid-state technology to your production line.