- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-10-14 Origin: Site

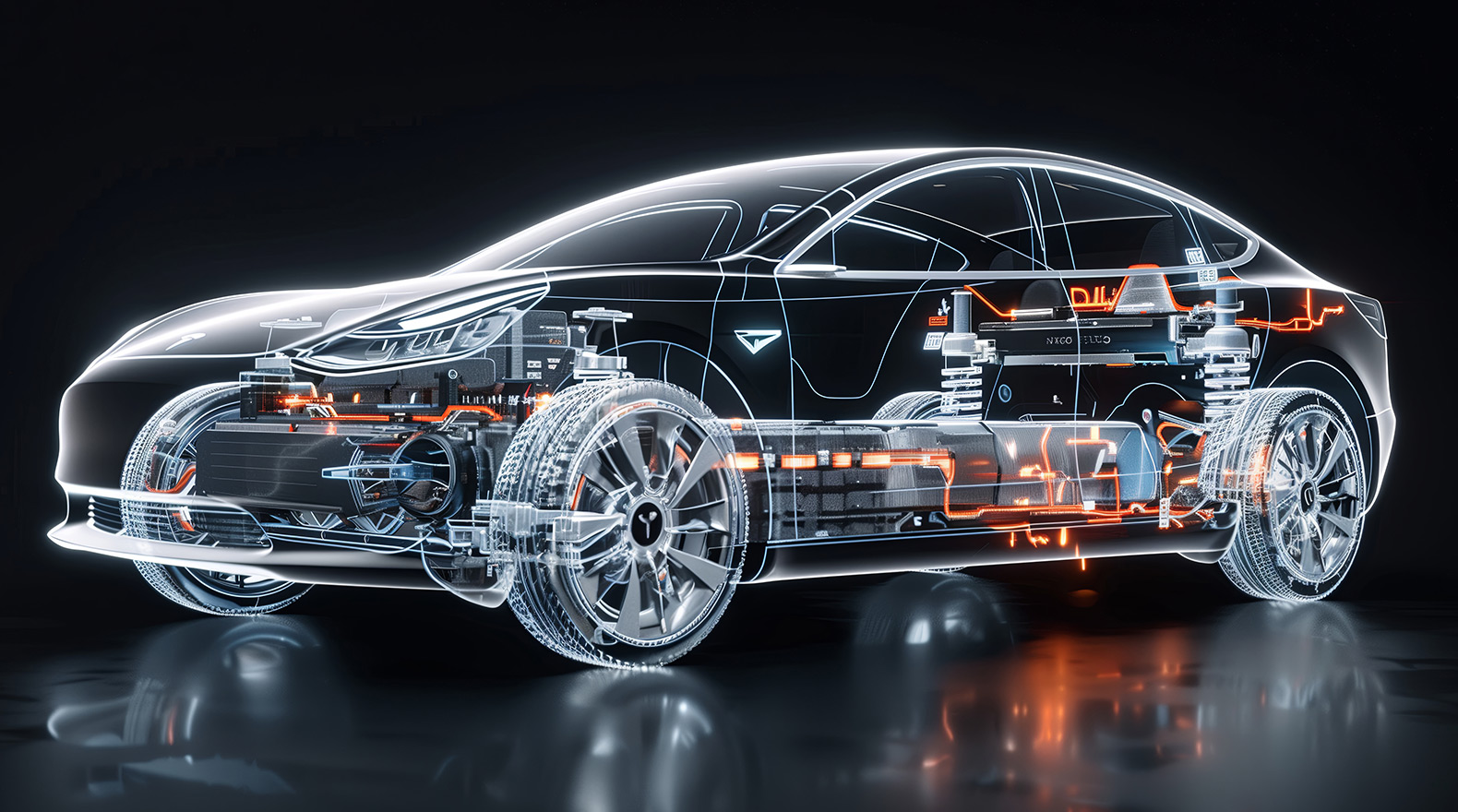

Electric vehicles are transforming transportation, but efficient battery housing is crucial. Friction Stir Welding offers a solution. This article explores its role in EV manufacturing, focusing on battery housings. You'll learn about advantages, technical aspects, and future prospects of this innovative welding technique.

Friction Stir Welding (FSW) offers several benefits compared to traditional welding methods, especially in manufacturing EV battery housings. Unlike fusion welding, FSW is a solid-state process that does not melt the metal. This results in minimal distortion and residual stresses. The friction stir welding process produces joints with excellent mechanical properties and superior fatigue resistance, crucial for battery housings that endure vibrations and impacts.

Additionally, FSW creates defect-free welds without the need for filler materials or flux. This reduces the risk of contamination and weak spots. The process also generates less heat, avoiding issues like warping or weakening of heat-sensitive materials such as aluminum alloys. With friction stir welding equipment, manufacturers can achieve consistent, high-quality joints in complex geometries.

Battery housings often require joining dissimilar materials, such as aluminum to steel or various aluminum alloys. The friction stir welding tool design enables effective joining of these heterogeneous materials. For instance, friction stir welding aluminium is widely used due to aluminum’s lightweight and corrosion resistance, which are vital for EV efficiency.

FSW welding stainless steel is also possible, expanding material options. The stir welding process promotes fine grain structures in the weld zone, enhancing strength and toughness. This microstructural refinement results in joints that maintain or exceed base material properties, ensuring the battery housing withstands mechanical stresses and thermal cycling.

Durability is a key factor for EV battery housings, which must protect sensitive cells from environmental factors and mechanical damage. Friction stir welding companies have demonstrated that FSW joints resist cracking and corrosion better than traditional welds.

The solid-state nature of FSW minimizes defects like porosity or inclusions that can compromise durability. Furthermore, the uniform grain structure in the stir zone improves wear resistance. This leads to longer-lasting battery housings capable of maintaining integrity throughout the vehicle’s lifetime.

Weight reduction is critical in EV design to maximize range and performance. Friction stir welding aluminium components allows manufacturers to use thinner, lighter materials without sacrificing strength. The absence of filler metals and reduced distortion also contributes to lighter assemblies.

High-speed friction stir welding machines enable efficient production of lightweight battery trays and enclosures. By optimizing welding parameters, manufacturers can balance speed and quality, supporting high-volume EV production while maintaining energy efficiency.

Safety is paramount in EV battery design. FSW provides hermetic seals that prevent moisture ingress, protecting electronics and battery cells. The process’s precision and repeatability ensure consistent joint quality, reducing the risk of failure.

Friction stir welding robots and automated equipment further enhance reliability by minimizing human error. The robust joints withstand impact and thermal stresses, critical for protecting passengers and vehicle components.

Tip: When selecting friction stir welding services for EV battery housings, prioritize suppliers with advanced tool design and proven experience in high-speed FSW aluminium applications to ensure optimal strength and durability.

Friction Stir Welding (FSW) is a solid-state joining process where a rotating friction stir welding tool generates heat through friction. This heat softens the materials without melting them, allowing the tool to stir and forge a strong joint. The fsw welding process involves plunging the tool’s pin into the workpieces and moving it along the joint line. The friction stir welding process creates a fine-grained microstructure, enhancing mechanical properties.

This process is especially suited for aluminium alloys, commonly used in electric vehicle battery housings for their lightweight and corrosion resistance. The stir welding process also works well for stainless steel and dissimilar metal joints, expanding its application scope in EV manufacturing.

The friction stir welding tool design is critical for process success. Tools typically consist of a shoulder and a probe (pin) made from wear-resistant materials like tool steel or tungsten alloys. The tool’s geometry—pin shape, shoulder diameter, and features like scrolls—affects material flow and heat generation.

For friction stir welding aluminium, tool designs often include a convex shoulder and threaded or tri-flat pins to optimize stirring action. When welding stainless steel or harder alloys, tool materials must withstand higher temperatures and forces. Advanced friction stir welding equipment integrates precise control over tool rotation speed and plunge depth to maintain consistent weld quality.

Welding parameters such as tool rotation speed, travel speed, axial force, and plunge depth must be carefully balanced. Higher rotation speeds increase heat generation, improving material plasticity but may cause excessive softening. Conversely, faster travel speeds reduce heat input, which can lead to defects.

Recent advances in high-speed friction stir welding (HSFSW) have pushed welding speeds up to 4.0 meters per minute in aluminium alloys, significantly improving production rates without compromising joint strength. Optimizing these parameters reduces cycle times, crucial for high-volume EV battery housing manufacturing.

High-speed friction stir welding introduces challenges like increased tool wear and risk of tool failure due to greater axial and transverse forces. Managing these forces requires robust friction stir welding tool designs and advanced stir welding machines capable of precise control.

Material mixing at high speeds can create joint line remnants or variations in microstructure, potentially affecting mechanical properties. However, studies show that with proper tool design and parameter optimization, defect-free high-speed welds with excellent strength and hardness profiles are achievable.

Automation using friction stir welding robots enhances consistency and reduces human error, further supporting high-speed, high-quality production in the EV industry.

Tip: When implementing friction stir welding for EV battery housings, prioritize advanced tool design and precise parameter control to achieve high-speed, defect-free welds that meet stringent strength and durability requirements.

Battery trays are critical components in electric vehicles, providing a secure enclosure for battery cells. Friction stir welding aluminium alloys is ideal here because it creates strong, lightweight joints without melting the metal. This ensures the trays remain rigid and impact-resistant while minimizing weight—a key factor for extending EV range. The fsw welding process also produces watertight seals, protecting sensitive battery cells from moisture and contaminants.

High-speed friction stir welding machines enable efficient production of these trays at scale, maintaining consistent quality. The friction stir welding tool design plays a vital role in achieving defect-free welds, especially when working with thin aluminum sheets common in battery tray construction.

The chassis and other structural parts of electric vehicles benefit greatly from friction stir welding. The process joins aluminum and steel components with high strength and minimal distortion. This is crucial for maintaining the structural integrity of the vehicle while keeping overall weight low.

Friction stir welding stainless steel parts is also gaining traction, allowing for hybrid structures that combine the best properties of both metals. Automated friction stir welding robots enhance precision and repeatability in assembling complex chassis components, ensuring safety and durability.

Beyond battery trays and chassis, friction stir welding supports the assembly of various EV systems. For example, it is used in manufacturing inverter housings, heat exchangers, and electronic enclosures, where strong, hermetic seals are needed.

The stir welding process allows joining dissimilar materials without compromising electrical conductivity or thermal management. This is essential for components that handle high voltages and require efficient cooling. Friction stir welding equipment designed for multi-material welding expands possibilities for integrated EV system manufacturing.

Tip: When choosing friction stir welding services for EV applications, select suppliers offering advanced friction stir welding tool design and automated stir welding machines to ensure high-quality, scalable production of battery trays and structural components.

Friction Stir Welding (FSW) is a solid-state welding process, meaning it joins metals without melting them. This contrasts with fusion welding techniques, which rely on melting and solidification. Because FSW avoids melting, it produces joints with less distortion and fewer defects like porosity or cracking. This is especially important for EV battery housings, where maintaining precise dimensions and structural integrity is critical.

Fusion welding can introduce residual stresses due to rapid cooling, which may weaken the joint over time. In contrast, the friction stir welding process generates heat through friction and plastic deformation, resulting in a refined microstructure with improved mechanical properties. For example, friction stir welding aluminium alloys commonly used in battery housings yields strong, fatigue-resistant joints that outperform fusion welds in durability.

When comparing efficiency, FSW often offers faster cycle times for certain applications, especially when using advanced friction stir welding equipment and robots. High-speed friction stir welding machines can produce consistent welds rapidly, supporting large-scale EV battery housing manufacturing.

Moreover, FSW requires no filler materials or shielding gases, reducing consumable costs and simplifying logistics. The stir welding process also lowers rework rates due to fewer weld defects, saving time and money. While initial investment in specialized FSW machines or stir welding robots can be high, the long-term benefits in quality and productivity often justify the cost.

Friction Stir Welding is considered an environmentally friendly welding method. It consumes less energy than fusion welding because it operates at lower temperatures and eliminates the need for consumables like flux or filler metals. This reduces waste generation and emissions during production.

Additionally, FSW's ability to join lightweight materials such as aluminium and dissimilar metals supports vehicle lightweighting efforts. Lighter EV battery housings contribute to improved energy efficiency and reduced carbon emissions over the vehicle’s lifetime. Thus, choosing friction stir welding aligns with sustainability goals in EV manufacturing.

Tip: When evaluating welding options for EV battery housings, consider friction stir welding for its superior joint quality, cost savings over time, and reduced environmental footprint compared to fusion welding methods.

The evolution of friction stir welding tools is a key driver in expanding FSW applications for EV battery housings. Modern friction stir welding tool designs focus on improving durability and efficiency. For example, tool materials have shifted to advanced alloys and composites that withstand higher temperatures and stresses, especially when welding tougher metals like stainless steel. Innovative pin profiles and shoulder geometries enhance material flow, reducing defects and improving joint quality.

These improvements allow friction stir welding equipment to operate at higher speeds and with greater precision. Automated stir welding machines now incorporate sensors and real-time monitoring to optimize the welding process dynamically. Additionally, friction stir welding robots equipped with advanced tool changers enable seamless switching between different tool designs, adapting to diverse materials and thicknesses during production.

High-speed friction stir welding (HSFSW) is transforming EV battery housing manufacturing by significantly boosting throughput. Recent developments have pushed welding speeds beyond traditional limits, reaching up to 4 meters per minute in aluminum alloys commonly used for battery trays. This acceleration is possible due to optimized friction stir welding tool design and enhanced stir welding machines that manage forces and heat input effectively.

Faster welding reduces cycle times, enabling manufacturers to meet growing EV production demands without compromising joint integrity. Although high-speed welding introduces challenges like increased tool wear and potential microstructural changes, ongoing research and advanced friction stir welding services address these issues. Automation with friction stir welding robots further ensures consistent quality at elevated speeds, making HSFSW a practical choice for large-scale EV assembly.

Beyond battery housings, friction stir welding is finding new roles across the EV industry. The process suits joining lightweight aluminum chassis components, structural reinforcements, and electronic enclosures. Its ability to weld dissimilar metals, such as aluminum to steel, supports innovative hybrid designs that optimize weight and strength.

Friction stir welding equipment is also adapted for complex geometries and multi-material assemblies, aligning with the modular nature of modern EVs. As manufacturers seek more integrated and reliable components, friction stir welding services offer tailored solutions that improve production flexibility and product performance.

Tip: Invest in friction stir welding equipment featuring the latest tool designs and robotic automation to unlock higher welding speeds and expand manufacturing capabilities for EV battery housings and beyond.

Friction Stir Welding (FSW) is revolutionizing EV battery housing manufacturing. It offers superior mechanical properties and defect-free welds compared to traditional methods. FSW enhances durability and efficiency by reducing weight and providing reliable hermetic seals. It supports high-speed production, crucial for meeting EV industry demands. Looking ahead, FSW's advancements in tool design and automation promise further integration into EV systems. Zhihui Welding offers cutting-edge friction stir welding solutions, delivering unmatched value through advanced tool design and automated equipment for high-volume production.

A: Friction Stir Welding (FSW) is a solid-state welding process that joins metals without melting them. It's used for EV battery housings due to its ability to create strong, defect-free welds with minimal distortion, enhancing durability and safety.

A: The friction stir welding process benefits aluminum EV battery housings by producing lightweight, corrosion-resistant joints with excellent mechanical properties, crucial for maintaining vehicle efficiency and safety.

A: Friction stir welding is preferred over traditional methods because it minimizes defects and residual stresses, ensuring stronger, more durable joints essential for EV battery housings.

A: Friction stir welding tool design is critical in EV manufacturing, optimizing material flow and heat generation to produce high-quality welds in aluminum and other materials used in battery housings.

A: Yes, friction stir welding services can join dissimilar metals, such as aluminum to steel, supporting innovative hybrid designs in EV battery housings and structural components.